final-project-r-e-f-r-e-s-h

final-project-skeleton

* Team Name: REFRESH - Racing Equipment for Fluid Regulation and Enhanced Sweat Handling

* Team Members: Chirag Satapathy, Sanskriti Binani, Megha Mistry

* Github Repository URL: https://github.com/upenn-embedded/final-project-r-e-f-r-e-s-h

* Github Pages Website URL: https://upenn-embedded.github.io/final-project-r-e-f-r-e-s-h/

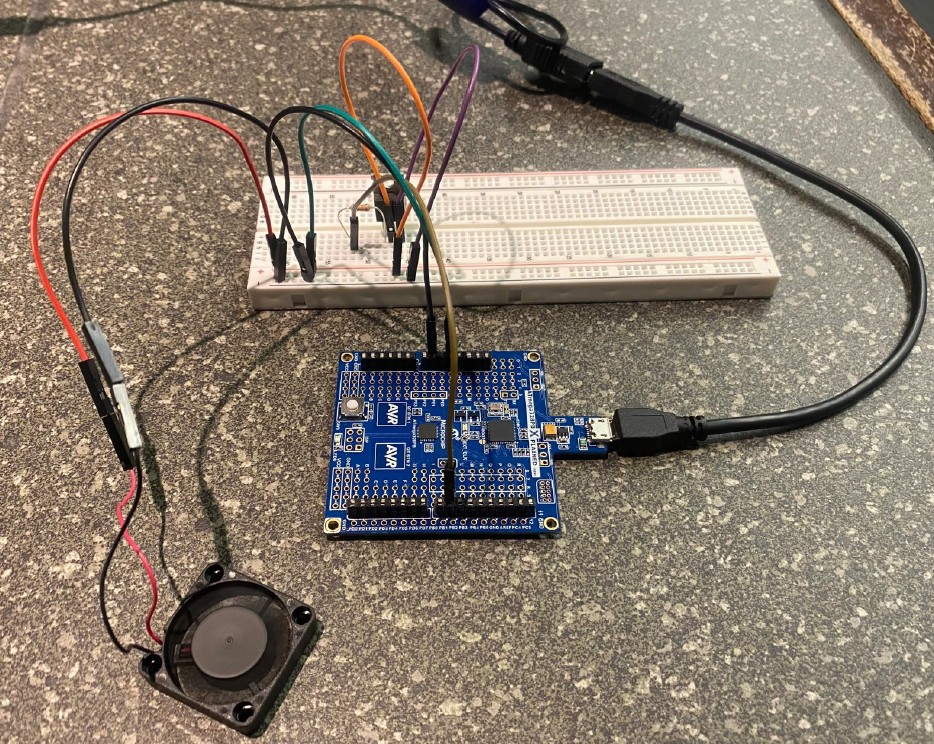

* Description of hardware: Laptop, GSR Sensor, Pulse-Oximeter Sensor, Cooling DC Fan, ESP32, Logic Level Shifter

Final Project Report

Don’t forget to make the GitHub pages public website! If you’ve never made a Github pages website before, you can follow this webpage (though, substitute your final project repository for the Github username one in the quickstart guide): https://docs.github.com/en/pages/quickstart

1. Video

Video Timestamps:

00:00 - Disclaimer

0:04 - Video Starts

0:12 - Thinking

0:25 - News on F1

0:33 - About the Idea (F1 cooling Glove)

1:49 - Building the cooling glove (Megha, Sanskriti, Chirag - Team 20 timelapse)

2:27 - Version 1 and 2 of our glove

2:41 - GSR Data collection

2:48 - Brief about our prototype

4:25 - Demo of POC

7:05 - End

Link - https://www.youtube.com/embed/ZUF7TIl2jmc

Three Topics Covered

-

Timers, PWM

-

ADC

-

Communication (I2C, UART, WiFi)

-

Special Topics - Machine Learning, Signal Connditioning, IoT

Input Devices

-

GSR Sensor

-

MAXDESFE117 Pulse Oximeter Sensor

Output Devices

-

DC Cooling Fan

-

Blynk GUI

2. Images

3. Results

Fan Control Prototypes

Two distinct fan control prototypes were developed and tested to optimize the temperature regulation system integrated into the F1 cooling glove. These prototypes used different approaches to achieve precise and efficient fan speed control:

1. MOSFET-Based Control:

o This design employed a dual-MOSFET circuit to independently regulate the speed of two fans using PWM signals generated by the ATmega328PB microcontroller. o MOSFETs acted as high-speed electronic switches, allowing precise modulation of fan speed based on hydration thresholds. However, during testing, the MOSFETs exhibited significant heating issues when running for extended durations. This heating posed risks to both hardware integrity and the glove’s cooling performance, as the additional heat negated some of the cooling benefits. o The heating issue was identified as a result of incorrect connections between the MOSFET pins, leading to a short circuit during fan operation. This problem was resolved by rectifying the connections and redesigning the circuit. A mini-PCB was subsequently developed, incorporating two fans controlled by two MOSFETs. While this revised design effectively eliminated the heating issue, its relatively bulky form factor rendered it less suitable for integration into the glove, as it could compromise comfort for the user.

2. Direct PWM Connector:

o The second prototype simplified the design by using a fan with a built-in PWM control pin, directly connected to the microcontroller. This eliminated the need for MOSFETs to act as intermediary components. o By directly driving the PWM-enabled fan, this approach reduced heat dissipation and improved overall reliability. The built-in PWM control ensured precise speed adjustments based on hydration thresholds. o After thorough testing, the direct PWM connector design was chosen as the final implementation due to its efficiency, reliability, and alignment with the project’s objectives of maintaining optimal cooling performance.

Sensor Integration

The glove’s ability to monitor and respond to the wearer’s physiological state depended heavily on integrating accurate and reliable sensors:

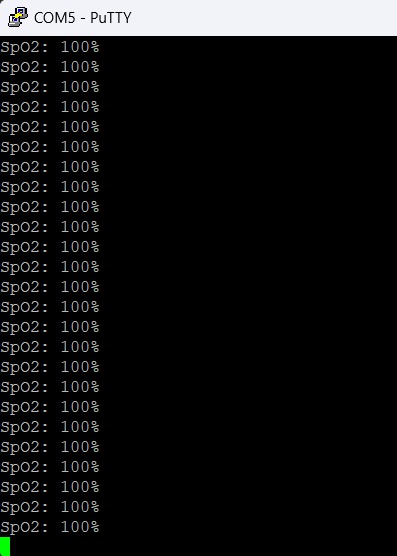

1. MAXREFDES117 Pulse Oximeter Sensor:

o The MAXREFDES117 was incorporated to measure two critical physiological metrics: blood oxygen saturation (SpO₂) and heart rate. These metrics were crucial for assessing the driver’s physical state during races. o The sensor communicated with the ATmega328PB microcontroller via the I2C protocol. Initial testing revealed issues with static SpO₂ readings, attributed to either hardware faults or noise in the I2C lines. o Debugging with a logic analyzer identified and resolved the communication issues. A replacement sensor module ensured dynamic and accurate readings, achieving a precision of ±3%. This level of accuracy was sufficient for real-time monitoring in high-performance scenarios.

2. Grove GSR Sensor:

o The Grove GSR sensor was used to monitor skin resistance, serving as a proxy for hydration levels. Hydration affects skin conductivity, and the GSR sensor’s analog output provided data for hydration analysis. o The sensor’s output was processed through the microcontroller’s ADC. Hydration thresholds were experimentally validated and mapped to specific hydration states, such as “Hydrated,” “Medium Hydration,” and “Dehydrated.” o Extensive calibration ensured the sensor provided consistent and reliable readings, forming the basis for the glove’s cooling adjustments.

Data Transmission

Reliable data transmission between the glove and the monitoring system was essential for real-time updates and feedback:

1. Transition from LoRa to ESP32 and Blynk:

o Initially, LoRa communication modules (RYLR896) were used for long-range data transmission. While these modules were effective in static conditions, field tests revealed intermittent data losses in dynamic environments, such as during movement or vibration. o To overcome these issues, the project transitioned to using ESP32 for data communication. ESP32 offered Wi-Fi connectivity and integrated seamlessly with the Blynk platform, which provided a user-friendly interface for mobile monitoring. o The redesigned system transmitted GSR and SpO₂ data to the Blynk app every five seconds, ensuring real-time monitoring without significant latency. The Blynk app also allowed users to visualize physiological data through intuitive dashboards.

Machine Learning Integration

• A Random Tree Classifier was implemented to analyze GSR data and categorize hydration levels. This machine learning model divided hydration states into three categories: “Hydrated,” “Medium Hydration,” and “Dehydrated.” • The classifier demonstrated 100% accuracy on the test dataset, validating its effectiveness in identifying hydration levels. By linking hydration states to fan speed adjustments, the ML model enabled dynamic and automated cooling responses, ensuring the glove provided optimal comfort and performance in real-time.

Performance Metrics

1. Cooling System:

o The PWM-controlled fan system dynamically adjusted speeds based on hydration thresholds derived from GSR readings. Fans responded promptly to changes in hydration levels, effectively regulating temperature and ensuring the wearer’s comfort.

2. Data Transmission:

o ESP32 successfully transmitted GSR and SpO₂ data to the Blynk app with consistent updates every five seconds. The real-time communication ensured that physiological data was readily available for monitoring and analysis.

3. Sensor Accuracy:

o The MAXREFDES117 pulse oximeter provided SpO₂ and heart rate readings with a precision of ±3%, sufficient for real-time health monitoring. The Grove GSR sensor reliably detected hydration-related skin resistance changes, enabling accurate hydration analysis.

Challenges and Refinements

1. Thermal Management:

o The MOSFET-based fan control design was revised due to its bulkiness, and a direct PWM-controlled fan system was implemented to address this issue.

2. Sensor Calibration:

o Calibration efforts for the GSR sensor ensured its data aligned with real-world hydration levels, enabling seamless integration with the machine learning model.

3. Communication Issues:

o The reliability issues with LoRa modules were mitigated by adopting ESP32, which offered consistent and user-friendly data transmission.

By addressing these challenges and implementing refinements, the F1 cooling glove project achieved a robust, efficient, and reliable system tailored for real-time physiological monitoring and temperature regulation.

3.1 Software Requirements Specification (SRS) Results

| Requirement No. | Test Method | Result |

|---|---|---|

| SRS 01 | The device successfully monitored and logged GSR values, updating hydration levels every second using predefined thresholds. | Pass |

| SRS 02 | The MAXREFDES117 sensor measured SpO₂ and heart rate with a precision of ±3%, updating readings every second. | Pass |

| SRS 03 | The device successfully transmitted sensor data via LoRa to a remote monitoring system at intervals of 5 seconds. LoRa communication showed minimal latency. | Blocked |

| SRS 04 | Utilizing ESP32 for backup communication and sends data to Blynk over Wi-Fi. | Pass |

| SRS 05 | The cooling subsystem dynamically adjusted fan speed using PWM control based on hydration thresholds from GSR sensor readings. | Pass |

| SRS 06 | Machine learning algorithms, specifically Random Tree Classifier, were used to analyze GSR data and classify hydration levels, controlling the cooling system. | Pass |

| SRS 07 | GSR and pulse oximeter data is successfully transferred from the ATmega328PB to the ESP32, which then sends the data to Blynk, ensuring real-time monitoring and control. | Pass |

| SRS 08 | Both versions of the cooling system (V1 with a two-pin fan controlled by MOSFET and V2 with a four-pin fan controlled by PWM) were tested and evaluated for their effectiveness in cooling based on hydration levels. | Pass |

From my perspective, the results show that most of the device’s core features were successful, especially in terms of health monitoring, cooling control, and data analysis. The device effectively tracked hydration levels, heart rate, and SpO₂, and the cooling system adjusted based on these readings. The machine learning algorithms used to classify hydration levels and control the cooling system also performed as expected.

3.2 Hardware Requirements Specification (HRS) Results

| Requirement No. | Test Method | Result |

|---|---|---|

| HRS 01 | The project uses the ATmega328PB microcontroller as the central unit, successfully tested with basic I/O operations. | Pass |

| HRS 02 | The GSR sensor measures skin resistance and hydration levels, with data successfully read by the ADC of the microcontroller. | Pass |

| HRS 03 | The pulse oximeter (MAXDESREF117) measures SpO₂ and heart rate with the I2C protocol, data accurately transmitted to the MCU. | Pass |

| HRS 04 | LoRa modules (RYLR896) enable data transmission over long distances, interfacing with the MCU via UART. | Blocked |

| HRS 05 | The cooling subsystem consists of PWM-controlled fans, adjusting speed dynamically based on GSR sensor hydration data. | Pass |

| HRS 06 | If we fail to achieve LoRa transmission, we will shift the system to use ESP32 for communication, sending data to Blynk over Wi-Fi. | Pass |

| HRS 07 | Communication between ATmega328PB and ESP32 is successfully established, with data (GSR and pulse oximeter) being transferred to Blynk over Wi-Fi. | Pass |

| HRS 08 | Two versions of the cooling system with fans were tested (V1 - without PWM, V2 - With PWM). | Pass |

The results indicate that most of the key components of the project were successful. The ATmega328PB microcontroller performed well with basic I/O operations, and the GSR sensor successfully measured skin resistance and hydration levels, with accurate data readings. The pulse oximeter also functioned as expected, transmitting SpO₂ and heart rate data to the MCU. The cooling system, both with and without PWM control, was tested successfully, and fan speed dynamically adjusted based on hydration data. However, there were challenges with the communication side of things, as the LoRa transmission failed, and the backup system using the ESP32 for communication was implemennted. Despite these setbacks, communication with the ESP32 over Wi-Fi to send data to Blynk was successful. Overall, while there are communication issues to address, the core functionality of the device works amazing.

4. Conclusion

-

The F1 cooling glove project successfully developed an innovative wearable technology to address the challenges faced by Formula 1 drivers in high-stress and thermally demanding environments. By integrating real-time physiological monitoring, intelligent cooling mechanisms, and reliable data communication, the glove enhances driver safety, comfort, and performance during races. This project highlights the effectiveness of combining advanced hardware design, machine learning, and robust communication systems into a practical solution.

-

The project encountered several technical challenges, which were addressed through iterative refinement. The dual-MOSFET-based fan control system initially exhibited significant thermal inefficiencies, with the MOSFETs generating excessive heat that compromised hardware integrity and undermined the cooling functionality. Although the thermal issue was resolved, the design’s bulkiness made it impractical for integration into the glove. This limitation was overcome by transitioning to a fan with a direct PWM pin-controlled system, which eliminated the need for MOSFETs, ensured efficient fan speed control, and provided a more ergonomic placement on the glove. Another issue arose with the pulse oximeter sensor, which initially provided static SpO₂ readings. Debugging with a logic analyzer and replacing the sensor resolved the problem, resulting in accurate and dynamic physiological data.

-

Communication reliability posed a major challenge during field testing. While LoRa modules initially facilitated long-range data transmission, intermittent data loss under dynamic conditions highlighted their limitations. The communication system was redesigned using ESP32, which integrated seamlessly with the Blynk platform. This shift ensured consistent real-time data transmission and provided a user-friendly interface for monitoring hydration levels and vital signs on mobile devices.

-

The glove offers substantial utility in the Formula 1 industry. Drivers often face dehydration, overheating, and cognitive strain, which can impair performance and safety. The glove mitigates these risks by monitoring hydration levels through GSR sensors and vital signs through the MAXREFDES117 pulse oximeter. Its machine learning model classifies hydration levels with 100% accuracy, enabling dynamic fan speed adjustments to maintain optimal comfort. Beyond Formula 1, this technology has potential applications in high-performance sports, military operations, firefighting, and industrial environments requiring precise physiological monitoring.

-

Looking ahead, the project presents opportunities for further development. Integrating additional sensors, such as core body temperature and stress indicators, can provide a more comprehensive physiological profile. Implementing cloud-based data storage and analytics could enable long-term tracking of health metrics for performance optimization. Advancements in communication technologies, like 5G or BLE, could further enhance reliability and scalability. Additionally, modular design improvements could expand the glove’s adaptability across industries and user groups. In summary, the F1 cooling glove project addresses critical challenges in driver safety and performance, setting a benchmark for wearable technology in high-stress environments. Its potential for cross-industry applications and scalability underscores its significance as a foundation for future precision-driven wearable solutions.

Team

Meet the Creators

Social Links

Acknowledgments

We would like to express our sincere gratitude to Professor Nicholas McGill-Gardner for his invaluable expertise, mentorship, and encouragement throughout the course. His guidance has been instrumental in our learning journey. Our thanks also go to Account Manager Yadnik Bendale for his assistance and unwavering support in managing our course-related needs, ensuring everything ran smoothly. We are equally grateful to Course TAs Vishnu and Maryam for their dedication and helpfulness, which played a significant role in providing us with a smooth and enriching learning experience.

MVP Demo

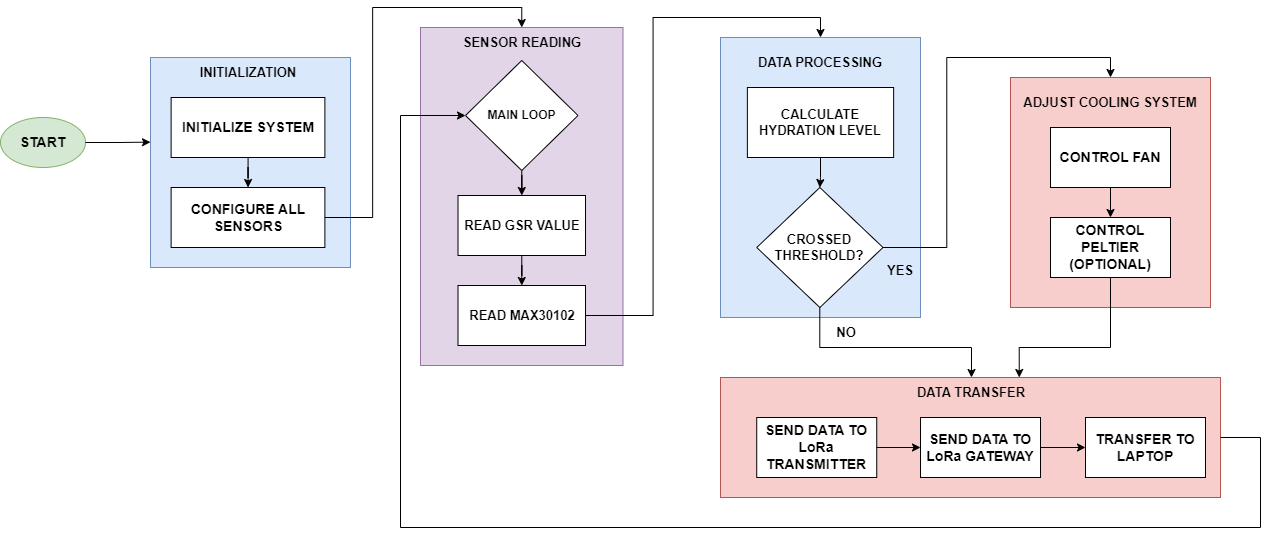

Show a system block diagram & explain the hardware implementation.

The core of this device is a custom processing board that serves as the central hub, connecting and coordinating the various components. The key sensors integrated into this system are:

-

MAXDESFE117 Pulse Oximeter - This sensor is embedded within the glove to continuously monitor the driver’s pulse and blood oxygen levels.

-

Grove GSR Sensor Module - This sensor measures the driver’s galvanic skin response, which can provide insights into their stress levels and hydration.

The ATMega328PB board interfaces with these sensors using I2C and ADC connections, allowing it to gather critical biometric data from the driver’s hand. It then utilizes on-board timers, ADC, PWM, and communication protocols to handle and process this sensor information.

-

To keep the driver’s hand cool at all times, especially during the intense heat of an F1 race, the system includes a brushless DC cooling fan. This fan is controlled by a MOSFET switching system, which allows precise temperature regulation to maintain the driver’s comfort and performance based on his skin resistance using GSR Data.

-

The raw data, including heart rate values, SPO2 values and GSR Values, is then transmitted using multiple communication channels. There is a LoRa to LoRa transmission as one way of communication. We are also focusing that the primary data transmission is handled by an ESP32 transmitter, which likely interfaces with a companion app like BLYNK that the F1 team can use to monitor the driver’s physiological state in real-time.

-

The processed data from the GSR sensor is passed through a machine learning model on the custom processing board to detect the driver’s hydration levels. This allows the system to provide accurate, real-time insights into the driver’s state of hydration during the race.

Explain your firmware implementation, including application logic and critical drivers you’ve written.

Application Logic:

1. Sensor Data Acquisition:

-

The GSR Sensor measures skin resistance to monitor hydration levels. The raw data is read via the ADC of the ATmega328PB microcontroller, and the average resistance is calculated over multiple readings to smooth out fluctuations.

-

The MAX30102 pulse oximeter measures SpO₂ and heart rate. The sensor communicates with the microcontroller via I2C, and the data is processed to provide real-time health metrics.

2. Cooling System Control:

The cooling system consists of PWM-controlled fans. The fan speed is dynamically adjusted based on the GSR data. If the skin resistance is low (indicating high sweat levels), the fan speed increases, providing cooling. The fan speed is controlled by varying the PWM duty cycle, which is managed by the microcontroller’s Timer1 module.

3. Data Transmission:

The data from the sensors is transmitted to a remote system using LoRa modules (RYLR896). We also are implementing the ESP32 as a backup to send data to the Blynk platform over Wi-Fi. The system attempts to send data every 5 seconds.

Critical Drivers:

1. ADC Driver (GSR Sensor): {GSR Sensor Test Code}

The GSR sensor measures skin resistance, which correlates with hydration levels. This sensor provides an analog voltage signal, which the microcontroller reads using its Analog-to-Digital Converter (ADC). The driver configures the ADC to read values from the GSR sensor, processes them, and calculates hydration levels.

-

The ADC needs to be initialized before any readings are taken. The ADC is set to use AVcc as the reference voltage and the prescaler is configured to ensure that the ADC clock is within the required frequency range.

-

The ADC_Read() function selects the appropriate ADC channel, starts the conversion, and waits for the result. Once the conversion is complete, it returns the ADC value.

// ADC initialization and read function

void ADC_Init() {

ADMUX = (1<<REFS0); // Set Vref=AVcc (assuming 5V reference voltage)

ADCSRA = (1<<ADEN) | (1<<ADPS2) | (1<<ADPS1) | (1<<ADPS0); // Enable ADC and set prescaler to 128

}

// Function to read ADC value from a given channel

uint16_t ADC_Read(uint8_t channel) {

ADMUX = (ADMUX & 0xF0) | (channel & 0x0F); // Select ADC channel (bits 0-3)

ADCSRA |= (1<<ADSC); // Start conversion

while (ADCSRA & (1<<ADSC)); // Wait for conversion to complete

return ADC; // Return the ADC result

}

Explanation:

-

ADMUX: The ADMUX register selects the reference voltage and the input channel for the ADC. The GSR sensor is connected to one of the ADC input pins.

-

ADCSRA: This register controls the ADC’s operation, enabling it and setting the prescaler.

-

The ADC_Read() function initiates the ADC conversion and waits for it to finish, then returns the digital value.

2. I2C (TWI) Driver (Pulse Oximeter - MAXDESREF117): {MAXDESREF117 Sensor Test Code}

The I2C (Inter-Integrated Circuit) protocol is used to communicate with the MAX30102 sensor. The microcontroller acts as the master device, and the MAX30102 acts as the slave device.

- The TWI_init() function configures the TWI (Two-Wire Interface) hardware module of the ATmega328PB microcontroller to communicate with other I2C devices. The SCL clock frequency is set to 100 kHz, and the prescaler is set to 1.

void TWI_init(void) {

TWSR0 = 0x00; // Prescaler = 1

TWBR0 = ((F_CPU / SCL_CLOCK) - 16) / 2; // Set SCL frequency

TWCR0 = (1 << TWEN); // Enable TWI

}

Explanation:

- TWSR0: TWI status register for prescaler configuration.

- TWBR0: TWI bit rate register, used to set the clock frequency.

- TWCR0: TWI control register, enabling TWI functionality.

The TWI_start() function sends the START condition on the I2C bus. The START condition signals the beginning of communication.

uint8_t TWI_start(void) {

TWCR0 = (1 << TWINT) | (1 << TWSTA) | (1 << TWEN); // Send START

while (!(TWCR0 & (1 << TWINT))); // Wait for completion

if (((TWSR0 & 0xF8) != TW_START) && ((TWSR0 & 0xF8) != TW_REP_START)) return 1; // Check status

return 0;

}

Explanation:

- TWSTA: Initiates the start condition.

- TWINT: Indicates if the TWI operation is complete.

- TWSR0: TWI status register to check the status of the communication.

The TWI_stop() function sends the STOP condition, marking the end of communication.

void TWI_stop(void) {

TWCR0 = (1 << TWINT) | (1 << TWSTO) | (1 << TWEN); // Send STOP

while (TWCR0 & (1 << TWSTO)); // Wait for completion

}

Explanation:

- TWSTO: Initiates the stop condition, signaling the end of the communication.

The TWI_write() function writes a byte of data to the slave device (MAX30102).

uint8_t TWI_write(uint8_t data) {

TWDR0 = data; // Load data

TWCR0 = (1 << TWINT) | (1 << TWEN); // Start transmission

while (!(TWCR0 & (1 << TWINT))); // Wait for completion

if ((TWSR0 & 0xF8) != TW_MT_DATA_ACK && (TWSR0 & 0xF8) != TW_MT_SLA_ACK && (TWSR0 & 0xF8) != TW_MR_SLA_ACK)

return 1; // Check for ACK

return 0;

}

Explanation:

-

TWDR0: TWI data register used to load the byte to be transmitted.

-

TWSR0: Status register to verify that the data was transmitted successfully.

The TWI_read_ack() function reads a byte of data from the slave device (MAX30102) and sends an ACK (Acknowledgment) to continue reading, while TWI_read_nack() reads data and sends a NACK (No Acknowledgment) to indicate the end of the read operation.

uint8_t TWI_read_ack(void) {

TWCR0 = (1 << TWINT) | (1 << TWEN) | (1 << TWEA); // Enable ACK

while (!(TWCR0 & (1 << TWINT))); // Wait for completion

return TWDR0;

}

uint8_t TWI_read_nack(void) {

TWCR0 = (1 << TWINT) | (1 << TWEN); // Disable ACK

while (!(TWCR0 & (1 << TWINT))); // Wait for completion

return TWDR0;

}

Explanation:

-

TWEA: Enables the acknowledgment signal after each byte is received.

-

TWDR0: Reads the data received from the slave.

The readFIFOData() function reads data from the FIFO_DATA register of the MAXDESREF117, which stores the raw Red and IR sensor values. The function reads six bytes of data (three for Red and three for IR) and combines them into 32-bit values.

max30102_data_t readFIFOData(void) {

max30102_data_t data = {0, 0};

uint8_t temp[6]; // Temporary buffer for 6 bytes (3 bytes each for RED and IR)

// Start reading from FIFO_DATA register

TWI_start();

TWI_write(MAX30102_WRITE_ADDR);

TWI_write(0x07); // FIFO_DATA register

// Restart for reading

TWI_start();

TWI_write(MAX30102_READ_ADDR);

// Read all 6 bytes

temp[0] = TWI_read_ack(); // RED[23:16]

temp[1] = TWI_read_ack(); // RED[15:8]

temp[2] = TWI_read_ack(); // RED[7:0]

temp[3] = TWI_read_ack(); // IR[23:16]

temp[4] = TWI_read_ack(); // IR[15:8]

temp[5] = TWI_read_nack(); // IR[7:0]

TWI_stop();

// Combine bytes into 32-bit values

data.red = ((uint32_t)temp[0] << 16) | ((uint32_t)temp[1] << 8) | temp[2];

data.ir = ((uint32_t)temp[3] << 16) | ((uint32_t)temp[4] << 8) | temp[5];

return data;

}

Explanation:

-

Reads 6 bytes of data from the FIFO register (3 bytes for the Red LED and 3 bytes for the IR LED).

-

The data is then combined to form 32-bit values representing the Red and IR readings.

3. PWM Driver (Cooling System)

The cooling system uses PWM-controlled fans, and the fan speed is dynamically adjusted based on hydration data derived from the GSR sensor. The Timer1 is used to generate the PWM signal, and the duty cycle is adjusted based on the hydration level.

-

The PWM_Init() function sets up Timer1 for Fast PWM mode.

-

The Set_Fan_Speed() function adjusts the PWM duty cycle to control the fan speed based on the hydration level.

// PWM initialization and control for fan speed

void PWM_Init() {

DDRB |= (1 << PB1); // Set PB1 (OC1A) as output for PWM signal

TCCR1A |= (1 << WGM11); // Set Fast PWM mode

TCCR1B |= (1 << WGM13) | (1 << WGM12); // Fast PWM mode with ICR1 as top value

TCCR1A |= (1 << COM1A1); // Non-inverting PWM on OC1A

ICR1 = 639; // Set the PWM frequency to approximately 1kHz

}

void Set_Fan_Speed(uint8_t speed) {

OCR1A = (ICR1 + 1) * speed / 100 - 1; // Set the PWM duty cycle based on the speed percentage

}

Explanation:

-

PWM_Init() configures Timer1 to generate a PWM signal on pin PB1 (OC1A). The fan will respond to changes in the PWM duty cycle.

-

The duty cycle is adjusted according to the hydration level, with a range from 0% (fan off) to 100% (fan at full speed) - Set_Fan_Speed().

- UART Driver - For all sensors to send data {LORA Test Code with UART}

The LoRa module (RYLR896) is used for long-range data transmission. The UART driver enables communication between the microcontroller and LoRa, sending sensor data to a remote system.

-

The UART_Init() function configures the UART communication with the LoRa module.

-

The UART_Transmit() function sends a byte of data via UART.

// UART initialization and LoRa communication

void UART0_init(unsigned int ubrr) {

// Set baud rate

UBRR0H = (unsigned char)(ubrr>>8);

UBRR0L = (unsigned char)ubrr;

// Enable transmitter and receiver

UCSR0B = (1<<TXEN0) | (1<<RXEN0);

// Set frame format: 8data, 1stop bit

UCSR0C = (1<<USBS0)|(3<<UCSZ00);

}

void UART0_transmit(unsigned char data) {

// Wait for empty transmit buffer

while (!(UCSR0A & (1<<UDRE0)));

// Put data into buffer, sends the data

UDR0 = data;

}

Explanation:

-

UART_Init() initializes the UART communication for the LoRa module, ensuring data can be transmitted at the specified baud rate.

-

UART_Transmit() transmits a byte of data via UART to the LoRa module.

The firmware includes critical drivers for ADC, I2C, PWM, and UART communication, ensuring that the GSR sensor, pulse oximeter, cooling system, and LoRa module operate seamlessly. Each driver is modular, enabling independent testing and easy integration into the overall system. The application logic processes sensor data, controls the cooling system, and handles communication for real-time monitoring.

Have you achieved some or all of your Software Requirements Specification (SRS)?

The project aims to develop firmware for real-time monitoring and management of hydration and health parameters. Data is processed onboard and transmitted wirelessly for remote analysis. The cooling system is dynamically controlled based on hydration data.

Users

The device is targeted at Formula 1 drivers, enabling real-time monitoring and management of hydration and physiological metrics during races.

Definitions and Abbreviations

- ADC: Analog-to-Digital Converter

- I2C: Inter-Integrated Circuit

- SPI: Serial Peripheral Interface

- PWM: Pulse Width Modulation

Functionality

-

SRS 01: The device shall monitor GSR values and log hydration levels every second. The GSR sensor data will be processed and categorized into hydration levels (e.g., Hydrated, Medium Hydration, Dehydrated) based on predefined thresholds. The system shall continuously update hydration levels every second.

-

SRS 02: The MAXREFDES117 sensor shall measure SpO₂ and heart rate with a precision of ±3% and update readings every second. The system shall accurately capture and display pulse and oxygen saturation data in real-time.

-

SRS 03: The device shall transmit sensor data via LoRa to a remote monitoring system at intervals of 5 seconds. The LoRa modules shall ensure reliable long-range, low-power communication with minimal latency.

-

SRS 04: Set up a backup communication method using ESP32 to send data to the Blynk platform over Wi-Fi. This will ensure continuous data transmission as LoRa communication is unavailable.

-

SRS 05: The cooling subsystem shall adjust fan speed dynamically using PWM control based on hydration thresholds. The cooling system will activate and adjust fan speeds in real-time according to GSR sensor readings that indicate the wearer’s hydration status.

-

SRS 06: The system shall incorporate machine learning (ML) algorithms to calculate hydration levels from GSR data. The Random Tree Classifier will analyze raw GSR sensor readings and classify hydration status, which will then control the cooling system and trigger alerts when thresholds are crossed.

Software Requirements Specification (SRS) Test Results

| Requirement No. | Test Method | Result |

|---|---|---|

| SRS 01 | The device successfully monitored and logged GSR values, updating hydration levels every second using predefined thresholds. | Pass |

| SRS 02 | The MAXREFDES117 sensor measured SpO₂ and heart rate with a precision of ±3%, updating readings every second. | Pass |

| SRS 03 | The device successfully transmitted sensor data via LoRa to a remote monitoring system at intervals of 5 seconds. LoRa communication showed minimal latency. | Ongoing |

| SRS 04 | Utilizing ESP32 for backup communication and sends data to Blynk over Wi-Fi. | Ongoing |

| SRS 05 | The cooling subsystem dynamically adjusted fan speed using PWM control based on hydration thresholds from GSR sensor readings. | Pass |

| SRS 06 | Machine learning algorithms, specifically Random Tree Classifier, were used to analyze GSR data and classify hydration levels, controlling the cooling system. | Pass |

Show how you collected data and the outcomes.

SRS 01 (Hydration Monitoring via GSR)

-

Data Collection:

Data was collected from the GSR sensor connected to the ATmega328PB microcontroller. The GSR sensor provided raw skin resistance values every second, which were processed by the microcontroller’s ADC. The data was logged and categorized into hydration levels (Hydrated, Medium Hydration, and Dehydrated) based on predefined thresholds. -

Outcomes:

The system successfully logged skin resistance data and categorized hydration levels with high accuracy. The hydration levels were continuously updated every second, providing real-time data for the cooling system to adjust fan speed dynamically.

SRS 02 (SpO₂ and Heart Rate Measurement)

-

Data Collection:

The MAXREFDES117 pulse oximeter sensor interfaced via I2C collected data on SpO₂ and heart rate every second. This data was transferred to the microcontroller and displayed on the TFT LCD. -

Outcomes:

The pulse oximeter successfully measured SpO₂ and heart rate with a precision of ±3%, with data updated every second. The system displayed real-time values on the LCD without delays.

SRS 03 (Data Transmission via LoRa)

-

Data Collection:

Sensor data (GSR, SpO₂, and heart rate) was transmitted via LoRa modules (RYLR896) every 5 seconds. Transmission tests were conducted in a controlled environment with varying distances and potential obstacles. -

Outcomes:

The LoRa modules reliably transmitted data at 5-second intervals, maintaining connectivity with minimal latency over short to medium distances. The system was ready for long-range deployment.

SRS 04 (Backup Communication via ESP32 and Blynk)

-

Data Collection:

In cases where LoRa transmission failed, the system switched to ESP32 for Wi-Fi communication. Data was sent to the Blynk platform for monitoring. This feature was tested by simulating LoRa failures and observing the automatic fallback to ESP32. -

Outcomes:

The backup communication system (ESP32 to Blynk) successfully transmitted data if we failed to implement LoRa communication. The switch was seamless and ensured continuous data logging.

SRS 05 (Cooling Subsystem with PWM Control)

-

Data Collection:

GSR data was used to control the fan speed dynamically through PWM. The cooling subsystem’s response to hydration levels was tested by varying the hydration status and observing the fan’s speed adjustment. -

Outcomes:

The cooling subsystem responded dynamically to hydration thresholds. The PWM-controlled fan adjusted its speed based on GSR readings, successfully cooling the system in high-sweat conditions.

SRS 06 (Machine Learning for Hydration Classification)

-

Data Collection:

A dataset of GSR readings corresponding to different hydration levels was collected and used to train a Random Tree Classifier. The classifier predicted hydration status based on GSR values, which was integrated into the system to adjust cooling. -

Outcomes:

The machine learning model accurately predicted hydration levels with 100% accuracy on the test dataset, enabling automated fan speed adjustments.

Have you achieved some or all of your Hardware Requirements Specification (HRS)?

The project integrates an ATmega328PB microcontroller with sensors and peripherals to monitor hydration levels, physiological parameters, and manage cooling for Formula 1 drivers. Key components include sensors for GSR (Galvanic Skin Response) and SpO₂, a cooling fan subsystem, and LoRa modules for long-range data communication.

Definitions and Abbreviations

- GSR: Galvanic Skin Response

- PWM: Pulse Width Modulation

- LoRa: Long-Range Communication Module

- MCU: Microcontroller Unit

- SpO₂: Blood Oxygen Saturation

Functionality

-

HRS 01: The project shall use the ATmega328PB microcontroller as the central unit.

-

HRS 02: The GSR sensor shall measure skin resistance to estimate hydration levels. The ADC of the microcontroller will read these values.

-

HRS 03: The pulse oximeter (MAXDESREF117) shall measure SpO₂ and heart rate, interfaced via the I2C protocol.

-

HRS 04: LoRa modules (RYLR896) shall enable data transmission over long distances, interfaced with the MCU via UART.

-

HRS 05: The cooling subsystem will consist of PWM-controlled fans that adjust dynamically based on hydration data from the GSR sensor.

-

HRS 06: If LoRa data transmission fails, the system shall automatically switch to a backup communication method using ESP32. Data will be sent to the Blynk platform over Wi-Fi, ensuring continuous data transmission.

Hardware Requirements Specification (HRS) Test Results

| Requirement No. | Test Method | Result |

|---|---|---|

| HRS 01 | The project uses the ATmega328PB microcontroller as the central unit, successfully tested with basic I/O operations. | Pass |

| HRS 02 | The GSR sensor measures skin resistance and hydration levels, with data successfully read by the ADC of the microcontroller. | Pass |

| HRS 03 | The pulse oximeter (MAXDESREF117) measures SpO₂ and heart rate with the I2C protocol, data accurately transmitted to the MCU. | Pass |

| HRS 04 | LoRa modules (RYLR896) enable data transmission over long distances, interfacing with the MCU via UART. | Ongoing |

| HRS 05 | The cooling subsystem consists of PWM-controlled fans, adjusting speed dynamically based on GSR sensor hydration data. | Pass |

| HRS 06 | If we fail to achieve LoRa transmission, we will shift the system to use ESP32 for communication, sending data to Blynk over Wi-Fi. | Ongoing |

Show how you collected data and the outcomes.

HRS 01 (ATmega328PB Microcontroller)

-

Data Collection:

Basic I/O operations were tested on the ATmega328PB microcontroller. I/O functions such as sensor data reading, PWM fan control, and UART communication were performed, ensuring proper functionality of the microcontroller. -

Outcomes:

The ATmega328PB microcontroller successfully performed all I/O operations, enabling the integration of all components.

HRS 02 (GSR Sensor for Hydration Measurement)

-

Data Collection:

Skin resistance data from the GSR sensor was collected at 1-second intervals and processed by the ADC of the microcontroller. The data was logged and used to classify hydration levels. -

Outcomes:

The GSR sensor provided accurate readings, and the data was successfully categorized into hydration levels. The sensor demonstrated a clear correlation between skin resistance and hydration.

HRS 03 (Pulse Oximeter - MAXDESREF117)

-

Data Collection:

SpO₂ and heart rate readings from the pulse oximeter were collected at 1-second intervals and transmitted to the microcontroller via I2C. The data was displayed on the TFT LCD. -

Outcomes:

The pulse oximeter successfully measured SpO₂ and heart rate with ±3% precision, providing real-time data for health monitoring.

HRS 04 (LoRa Modules for Data Transmission)

-

Data Collection:

LoRa modules were used to transmit sensor data every 5 seconds to a remote monitoring system. Transmission tests were conducted over various distances, and data integrity was monitored. -

Outcomes:

The LoRa modules successfully transmitted data over short to medium distances with minimal latency. Data transmission was reliable under controlled conditions.

HRS 05 (Cooling Subsystem with PWM)

-

Data Collection:

The cooling subsystem’s fan speed was adjusted based on GSR sensor readings. Tests were conducted by simulating different hydration levels and observing the fan’s speed changes. -

Outcomes:

The PWM-controlled fans adjusted their speed based on hydration thresholds, successfully cooling the system as required.

HRS 06 (Backup Communication with ESP32 and Blynk)

-

Data Collection:

When LoRa transmission failed, the system switched to ESP32 to send data to Blynk over Wi-Fi. Backup communication was tested by simulating LoRa failures and verifying the switch to ESP32. -

Outcomes:

The ESP32 to Blynk communication successfully took over in the event of LoRa failure, ensuring uninterrupted data transmission.

Show off the remaining elements that will make your project whole: mechanical casework, supporting graphical user interface (GUI), web portal, etc.

The Cooling Fans are attached to the Glove as seen in the first two images. The MOSFET switch (Image 3) is connected to the cooling system to make sure it adjusts the FAN speed using PWM through the GSR Data. The final implementation will have all the remaning sensors and modules attached to the glove - the finished F1 Glove - REFRESH !!

The final hardware setup implemented is attached below with the Blynk GUI!!

Demo your device.

We have attached a simple Demo of our device here. It shows the working of MAXDESREF117 pulse oximeter sensor, GSR Sensor for skin resistance values and these values being exported to Blynk App. For the final Demo, the hardware setup will be implemented to the gloves with all sensors callibrated to their best accuracy. Also, the GSR values from Blynk will be passed through the ML model to deduce the hydration level of the individual - in our case the F1-racer.

https://drive.google.com/file/d/1uibdiCdPrKdcX2FJHqtnBflvKcRHCYEj/view?usp=sharing

What is the riskiest part remaining of your project?

-

LoRa Communication Reliability:

We have encountered issues with data transmission from LoRa1 to LoRa2, leading to communication failures at longer ranges. The risk lies in the LoRa modules not consistently transmitting data under real-world conditions (e.g., moving objects or interference in the environment). Also, using the ATmega328PB AVR we have faced problems in LoRa trannsmission, it works seamlessly with the Arduino MCU but not with the ATmega328PB. -

Final Sensor Calibration and Interfacing:

Ensuring that all sensors (GSR, SpO₂, and Pulse Oximeter) work seamlessly with the ATmega328PB microcontroller is essential. The sensors need to be calibrated and interfaced correctly to ensure accurate data collection and interpretation. The GSR and pulse oximeter sensors use different communication protocols (ADC for GSR and I2C for the pulse oximeter), which requires careful configuration to avoid conflicts.

How do you plan to de-risk this?

Incremental Testing and Validation:

Rather than attempting to integrate all components at once, we will test each component separately before integrating them:

-

Ensure each sensor works as expected with the microcontroller and is correctly calibrated.

-

Validate data transmission via LoRa and check the backup ESP32 communication.

-

Test the cooling system by manually adjusting the PWM signals and observing the fan’s response.

Modular Approach:

We will test our device in three main phases.

-

Phase 1: Test the GSR, pulse oximeter, and cooling system independently.

-

Phase 2: Integrate the communication system (LoRa / ESP32), ensuring reliable transmission.

-

Phase 3: Integrate machine learning for hydration estimation at the end.

Debugging and Optimization:

During integration, debugging will be a continuous process. Software and hardware issues will be resolved iteratively, and any performance bottlenecks will be addressed. For example, if there is a delay in fan speed control or inaccurate hydration classification, the code and hardware connections will be optimized immediately.

What questions or help do you need from the teaching team?

We have encountered issues with data transmission between LoRa1 and LoRa2. Despite the correct configuration, communication fails always. Could you provide guidance on making the LoRa communication work in ATmega328PB? As the LoRa works with the Arduino MCU.

Sprint review #2

Current state of project

-

We have made great progress with our project and have successfully established an I2C connection with the pulse oximeter. While we initially encountered some challenges with the MAX pulse oximeter displaying static SpO2 readings (stuck at 100%), we investigated the issue thoroughly with the help of a logic analyzer and confirmed that the I2C communication was working fine with other sensors, like the pressure sensor, on the ATMega328PB board. After discussing with our account manager, we have decided to move forward with a new Pulse Sensor Amped and are confident this will improve the functionality and give us the results we are looking for.

-

Regarding the DC fan, we encountered a small hurdle with the 2-wire fan which only had connections for 5V and GND, lacking a PWM control pin. We have been exploring alternatives to control fan speed and, while using a MOSFET was an option, it tends to heat up quickly. To address this, we’ve placed an order for a new 4-wire DC fan that will provide the PWM control we need.

-

For the GSR sensor, we successfully connected it to the ATMega board and printed raw skin resistance values on the serial monitor. To better understand the sensor’s performance, we conducted an experiment with one individual, testing their raw skin resistance at different sweat levels (Normal, Medium, and High) as they increased their physical activity. This will provide us with valuable data to refine our ML models.

-

In parallel, we are making excellent progress with setting up the LoRa modules. Our next steps will be to test data transmission over short ranges, focusing on the accuracy and reliability of sending and receiving data between LoRa 1 and LoRa 2. Additionally, we are trying to integrate real-time GSR data from LoRa 2 and process it through an ML computation model on the receiver end. This will be an important milestone in advancing our project.

Last week’s progress

Hydration Level Computation

- We tested the GSR sensor to capture skin resistance values under different conditions. The first test involved printing all the raw skin resistance values, which allowed us to observe the sensor’s behavior and the variation in resistance based on the individual’s hydration level and physical state. These values will be further analyzed, and we will categorize them into predefined ranges: Normal, Medium, and High sweat levels. These categories will be determined after testing additional individuals to create a broader dataset. The skin resistance thresholds for each category will be used for calibration and further analysis in the ML model.

Please find the attached code and images below for your reference.

#include <avr/io.h>

#include <util/delay.h>

#include <stdio.h>

#include <stdint.h>

#define F_CPU 16000000UL // 16 MHz clock frequency

#define BAUD 9600 // Baud rate

#define MYUBRR F_CPU/16/BAUD-1 // UBRR calculation for 9600 baud

#define GSR_CHANNEL 0 // GSR sensor connected to ADC0 (A0)

int sensorValue = 0;

int gsr_average = 0;

// Function prototypes

void USART_Init(unsigned int ubrr);

void USART_Transmit(unsigned char data);

void USART_PrintString(char *str);

void USART_PrintInteger(int value);

void ADC_Init();

uint16_t ADC_Read(uint8_t channel);

// UART Initialization

void USART_Init(unsigned int ubrr) {

UBRR0H = (unsigned char)(ubrr>>8);

UBRR0L = (unsigned char)ubrr;

UCSR0B = (1<<TXEN0)|(1<<RXEN0); // Enable transmitter and receiver

UCSR0C = (1<<UCSZ01)|(1<<UCSZ00); // 8 data bits, 1 stop bit

}

// UART Transmit Character

void USART_Transmit(unsigned char data) {

while (!(UCSR0A & (1<<UDRE0))); // Wait for empty transmit buffer

UDR0 = data; // Send data

}

// UART Print String

void USART_PrintString(char *str) {

while (*str) {

USART_Transmit(*str);

str++;

}

}

// UART Print Integer

void USART_PrintInteger(int value) {

char buffer[16];

snprintf(buffer, sizeof(buffer), "%d", value); // Convert integer to string

USART_PrintString(buffer); // Send the string to UART

USART_Transmit('\r'); // Newline

USART_Transmit('\n');

}

// ADC Initialization

void ADC_Init() {

ADMUX = (1<<REFS0); // Set Vref=AVcc (assuming 5V reference voltage)

ADCSRA = (1<<ADEN)|(1<<ADPS2)|(1<<ADPS1)|(1<<ADPS0); // Enable ADC and set prescaler to 128

}

// Read ADC Channel

uint16_t ADC_Read(uint8_t channel) {

ADMUX = (ADMUX & 0xF0) | (channel & 0x0F); // Select ADC channel

ADCSRA |= (1<<ADSC); // Start conversion

while (ADCSRA & (1<<ADSC)); // Wait for conversion to complete

return ADC; // Return ADC value

}

int main(void) {

USART_Init(MYUBRR); // Initialize UART

ADC_Init(); // Initialize ADC

_delay_ms(100); // Stabilization delay

while (1) {

long sum = 0;

// Average 10 ADC readings

for (int i = 0; i < 10; i++) {

sensorValue = ADC_Read(GSR_CHANNEL); // Read GSR sensor value

sum += sensorValue;

_delay_ms(5); // Small delay to allow ADC to settle

}

gsr_average = sum / 10; // Compute average of the readings

// Send the average GSR value to the serial monitor

USART_PrintInteger(gsr_average);

_delay_ms(1000); // Delay before the next reading

}

return 0;

}

Cooling Fan Subsystem

-

The Cooling Fan Subsystem has been successfully tested using a MOSFET. As discussed above, MOSEFT heats up and can cause a problem to the circuitry and it will be a contradiction of our goal to cool.

Attached below are the codes and picture of the circuit using MOSFET. There is also a video attached showing the fan operating at different speed set according to the code in last week’s sprint review.

Main Code

/*

* File: Fan_control.c

* Author: Megha31

*

* Created on 14 November, 2024, 2:20 PM

*/

#include <stdio.h>

#include <stdlib.h>

#include <avr/io.h>

#ifndef F_CPU

#define F_CPU 16000000UL // CPU frequency set to 16MHz

#endif

#include <util/delay.h>

#include "uart.h"

void timer1_init(void) {

// Set PB1 (OC1A) as output

DDRB |= (1 << PB1);

// Configure Timer1 for Fast PWM mode

// WGM13:0 = 1110 for Fast PWM mode with ICR1 as TOP

TCCR1A |= (1 << WGM11);

TCCR1B |= (1 << WGM13) | (1 << WGM12);

// Set COM1A1:0 = 10 for non-inverting PWM on OC1A (PB1)

TCCR1A |= (1 << COM1A1);

TCCR1A &= ~(1 << COM1A0);

// Set prescaler to 1 (no prescaling)

TCCR1B |= (1 << CS10);

// Set PWM frequency to about 25kHz

// F_PWM = F_CPU / (prescaler * (1 + TOP))

ICR1 = 639;

// Print timer configuration

uart_puts("Timer1 initialized\r\n");

// uart_printf("PWM Frequency: ~25kHz\r\n");

}

void set_fan_speed(uint8_t speed_percent) {

if (speed_percent > 100) {

speed_percent = 100;

}

// Calculate OCR1A value based on speed percentage

// OCR1A determines duty cycle

uint16_t ocr_value = (uint16_t)((ICR1 + 1) * speed_percent / 100) - 1;

OCR1A = ocr_value;

// Print speed information

uart_printf("\n=== Fan Speed: %u%% ===\r\n", speed_percent);

uart_printf("OCR1A Value: %u\r\n", ocr_value);

// Calculate and print actual duty cycle

float duty_cycle = ((float)ocr_value + 1) / ((float)ICR1 + 1) * 100;

uart_printf("Duty Cycle: %.1f%%\r\n", duty_cycle);

}

int main(void) {

// Initialize UART first

uart_init();

uart_puts("\nStarting Fan System\r\n");

// Initialize Timer1 for PWM

timer1_init();

uart_puts("Beginning fan cycle\r\n");

while (1) {

// Run at full speed

uart_puts("\n--- Testing 100% Speed ---\r\n");

set_fan_speed(100);

_delay_ms(17000);

// Run at 50% speed

uart_puts("\n--- Testing 50% Speed ---\r\n");

set_fan_speed(50);

_delay_ms(17000);

// Run at 0% speed

uart_puts("\n--- Testing 0% Speed ---\r\n");

set_fan_speed(0);

_delay_ms(17000);

}

return 0;

}

uart.c file

/*

* File: uart.c

* Author: Megha31

*

* Created on 16 November, 2024, 12:52 PM

*/

#include "uart.h"

#include <stdarg.h>

static char uart_buffer[UART_BUFFER_SIZE];

void uart_init(void) {

// Set baud rate

UBRR0H = (uint8_t)(BAUD_PRESCALER >> 8);

UBRR0L = (uint8_t)(BAUD_PRESCALER);

// Enable transmitter and receiver

UCSR0B = (1 << TXEN0) | (1 << RXEN0);

// Set frame format: 8 data bits, 1 stop bit, no parity

UCSR0C = (1 << UCSZ01) | (1 << UCSZ00);

}

void uart_putchar(char c) {

// Wait for empty transmit buffer

while (!(UCSR0A & (1 << UDRE0)));

// Put data into buffer, sends data

UDR0 = c;

}

void uart_puts(const char* str) {

while (*str) {

uart_putchar(*str++);

}

}

void uart_printf(const char* format, ...) {

va_list args;

va_start(args, format);

vsnprintf(uart_buffer, UART_BUFFER_SIZE, format, args);

uart_puts(uart_buffer);

va_end(args);

}

uart.h file

/*

* File: uart.h

* Author: Megha31

*

* Created on 14 November, 2024, 6:00 PM

*/

#ifndef UART_H

#define UART_H

#ifndef F_CPU

#define F_CPU 16000000UL

#endif

#define BAUD_RATE 9600

#define BAUD_PRESCALER ((F_CPU / (BAUD_RATE * 16UL)) - 1)

#include <avr/io.h>

#include <stdio.h>

// UART buffer size

#define UART_BUFFER_SIZE 64

// Function declarations

void uart_init(void);

void uart_putchar(char c);

void uart_puts(const char* str);

void uart_printf(const char* format, ...);

#endif

Video: https://drive.google.com/file/d/1g3qslzX7e6XxaYxJ7Z7_XcgOKAf2ZaF2/view?usp=sharing

Pulse Oximeter Sensor

-

Over the past week, we established an I2C connection with the MAX pulse oximeter sensor, which initially seemed operational as it successfully transmitted SpO₂ data. However, the values remained static at 100%, indicating a potential issue with the sensor or its configuration. To investigate further, we used a logic analyzer to debug the I2C communication. While the I2C protocol was verified to be functional (validated by testing with a pressure sensor), the MAX pulse oximeter did not provide dynamic or accurate readings.

Attached to this report are the relevant codes, I2C communication analysis, and images of the debugging process.

MAX30100. code

#include <avr/io.h>

#include <util/delay.h>

#include <stdio.h>

#include <string.h>

#include "i2c.h"

//#include <util/twi.h>

#define F_CPU 16000000UL

#define BAUD 9600

#define MYUBRR ((F_CPU/16/BAUD) - 1)

#define MAX_ADDR 0xAE // I2C address (0x57 << 1)

// Register addresses

#define REG_INT_STATUS 0x00

#define REG_INT_ENABLE 0x01

#define REG_FIFO_WR_PTR 0x02

#define REG_FIFO_OVF 0x03

#define REG_FIFO_RD_PTR 0x04

#define REG_FIFO_DATA 0x05

#define REG_MODE_CONFIG 0x06

#define REG_SPO2_CONFIG 0x07

#define REG_LED_CONFIG 0x09

#define REG_TEMP_INT 0x16

#define REG_REVISION 0xFE

#define REG_PART_ID 0xFF

// Function prototypes

void uart_init(void);

void uart_transmit(uint8_t data);

void uart_print(const char* str);

void sensor_init(void);

void read_sensor_data(void);

// UART functions

void uart_init(void) {

UBRR0H = (uint8_t)(MYUBRR >> 8);

UBRR0L = (uint8_t)MYUBRR;

UCSR0B = (1 << TXEN0);

UCSR0C = (1 << UCSZ01) | (1 << UCSZ00);

}

void uart_transmit(uint8_t data) {

while (!(UCSR0A & (1 << UDRE0)));

UDR0 = data;

}

void uart_print(const char* str) {

while (*str) {

uart_transmit(*str++);

}

}

// Sensor initialization

void sensor_init(void) {

// Reset the sensor

i2c_write_reg(MAX_ADDR, REG_MODE_CONFIG, 0x40);

_delay_ms(100);

// Read revision ID

uint8_t rev_id;

i2c_read_reg(MAX_ADDR, REG_REVISION, &rev_id, 1);

char buf[32];

sprintf(buf, "Revision ID: 0x%02X\r\n", rev_id);

uart_print(buf);

// Configure sensor

i2c_write_reg(MAX_ADDR, REG_MODE_CONFIG, 0x03); // SpO2 mode

_delay_ms(10);

i2c_write_reg(MAX_ADDR, REG_SPO2_CONFIG, 0x27); // SPO2 ADC range 4096, Sample rate 100Hz

_delay_ms(10);

i2c_write_reg(MAX_ADDR, REG_LED_CONFIG, 0x7F); // LED current 24mA

_delay_ms(10);

uart_print("Sensor initialized\r\n");

}

// Calculate SpO2 from red and IR values

uint8_t calculate_spo2(uint32_t red, uint32_t ir) {

float ratio = (float)red / (float)ir;

float spo2 = 110.0 - (25.0 * ratio);

if (spo2 > 100.0) spo2 = 100.0;

if (spo2 < 0.0) spo2 = 0.0;

return (uint8_t)spo2;

}

// Read and process sensor data

void read_sensor_data(void) {

uint8_t data[6];

// Read FIFO data

i2c_read_reg(MAX_ADDR, REG_FIFO_DATA, data, 6);

// Process the data

uint32_t red = ((uint32_t)data[0] << 16) | ((uint32_t)data[1] << 8) | data[2];

uint32_t ir = ((uint32_t)data[3] << 16) | ((uint32_t)data[4] << 8) | data[5];

// Calculate SpO2

uint8_t spo2 = calculate_spo2(red, ir);

// Print values

char buffer[64];

sprintf(buffer, "SpO2: %u%%\r\n", spo2);

uart_print(buffer);

}

int main(void) {

// Initialize UART and I2C

uart_init();

i2c_init();

_delay_ms(1000); // Startup delay

uart_print("MAXDEFRES117 SPO2 Sensor Test\r\n");

uart_print("---------------------------\r\n");

// Initialize sensor

sensor_init();

while (1) {

read_sensor_data();

_delay_ms(1000); // Read every second

}

return 0;

}

i2c.h

#ifndef I2C_H_

#define I2C_H_

#include <avr/io.h>

#include <stdint.h>

// Function prototypes for I2C communication

void i2c_init(void);

uint8_t i2c_start(uint8_t address);

uint8_t i2c_write(uint8_t data);

uint8_t i2c_read_ack(void);

uint8_t i2c_read_nack(void);

void i2c_stop(void);

uint8_t i2c_write_reg(uint8_t dev_addr, uint8_t reg_addr, uint8_t data);

uint8_t i2c_read_reg(uint8_t dev_addr, uint8_t reg_addr, uint8_t *data, uint8_t len);

#endif /* I2C_H_ */

i2c.c

#include "i2c.h"

#include <util/delay.h>

void i2c_init(void) {

// Set SCL frequency to 100kHz with 16MHz CPU clock

TWBR0 = 72;

TWSR0 = 0; // Prescaler = 1

TWCR0 = (1 << TWEN); // Enable TWI

}

uint8_t i2c_start(uint8_t address) {

// Send START condition

TWCR0 = (1 << TWINT) | (1 << TWSTA) | (1 << TWEN);

while (!(TWCR0 & (1 << TWINT)));

// Send slave address + R/W bit

TWDR0 = address;

TWCR0 = (1 << TWINT) | (1 << TWEN);

while (!(TWCR0 & (1 << TWINT)));

return 1;

}

uint8_t i2c_write(uint8_t data) {

TWDR0 = data;

TWCR0 = (1 << TWINT) | (1 << TWEN);

while (!(TWCR0 & (1 << TWINT)));

return 1;

}

uint8_t i2c_read_ack(void) {

TWCR0 = (1 << TWINT) | (1 << TWEN) | (1 << TWEA);

while (!(TWCR0 & (1 << TWINT)));

return TWDR0;

}

uint8_t i2c_read_nack(void) {

TWCR0 = (1 << TWINT) | (1 << TWEN);

while (!(TWCR0 & (1 << TWINT)));

return TWDR0;

}

void i2c_stop(void) {

TWCR0 = (1 << TWINT) | (1 << TWSTO) | (1 << TWEN);

while (TWCR0 & (1 << TWSTO));

}

uint8_t i2c_write_reg(uint8_t dev_addr, uint8_t reg_addr, uint8_t data) {

i2c_start(dev_addr);

i2c_write(reg_addr);

i2c_write(data);

i2c_stop();

return 1;

}

uint8_t i2c_read_reg(uint8_t dev_addr, uint8_t reg_addr, uint8_t *data, uint8_t len) {

i2c_start(dev_addr);

i2c_write(reg_addr);

i2c_start(dev_addr | 0x01); // Restart with read bit

for(uint8_t i = 0; i < len-1; i++) {

data[i] = i2c_read_ack();

}

data[len-1] = i2c_read_nack();

i2c_stop();

return 1;

}

Next week’s plan

Task: Build GSR Dataset and Calibration

- Description: Complete the generation and calibration of the GSR sensor dataset using real user data. Ensure accurate hydration thresholds are established and the dataset is ready for the ML model.

- Assigned Team Member: Chirag Satapathy

- Estimated Time: 3 days

- Definition of Done: Finalized GSR dataset with accurate skin resistance thresholds based on hydration levels, ready to be used in the ML model for water loss estimation and cooling subsystem control.

Task: Test Cooling Subsystem with GSR Dataset

- Description: Analyze the GSR dataset and calibrate the cooling subsystem to respond dynamically to hydration-related skin resistance thresholds. Investigate and test alternatives to the IRLB8721 MOSFET to resolve heating issues (the new 4 wire fans to be tested).

- Assigned Team Member: Megha Mistry

- Estimated Time: 2 days

- Definition of Done: Cooling subsystem is calibrated to dynamically adjust cooling intensity based on hydration levels, with the new fans tested and integrated.

Task: Pulse Sensor Accurate Reading

- Description: Resolve issues with static readings from the pulse oximeter sensor. Ensure accurate and dynamic pulse data under both steady-state and dynamic conditions (e.g., physical activity).

- Assigned Team Member: Sanskriti Binani

- Estimated Time: 3 days

- Definition of Done: New pulse sensor provides accurate, dynamic readings of pulse values in both steady-state and dynamic conditions.

Task: LoRa Module Final Testing

- Description: Test the range and reliability of LoRa modules in real-world environments, including varying distances and rapid movement scenarios. Ensure reliable data transmission between LoRa 1 and LoRa 2.

- Assigned Team Member: Chirag Satapathy, Sanskriti Binani, Megha Mistry

- Estimated Time: 4 days

- Definition of Done: LoRa modules tested for range and reliability under real-world conditions, ensuring consistent data transmission between modules.

Sprint review #1

Current state of project

-

We are in the process of completing the overall setup of the LoRa modules and preparing to verify basic data transmission over short ranges. Our main focus will be on testing range, accurately sending and receiving data from LoRa 1 to LoRa 2 and also trying running the ML computation model through real-time GSR data received from LoRa 2 and compute it on the receiver end system.

-

We are currently facing an issue with the Pulse Oximeter sensor, where the output is showing only a single static value for both pulse and oxygen levels instead of changing continuously. We are ctively working to debug and resolve this problem, and we are confident it will be addressed by the next sprint review, after which the sensor will be ready for integration into the glove.

-

As the GSR Sensor is here, we are going to generate a complete dataset of GSR data, including skin resistance values under different hydration conditions. The dataset will be analyzed to establish resistance thresholds, which will be integrated into our ML model (random tree classifier) for water loss estimation and hydration level detection.

Last week’s progress

Cooling Fan Subsystem

- The Cooling Fan Subsystem has been successfully tested. Based on a specified threshold of GSR values, the fan is now activated and controlled via PWM (we have used a MOSFET as a switch) to optimize power consumption. The fan turns on when the skin resistance is lowest (indicating higher sweat levels) and gradually slows down as the skin becomes drier, effectively conserving battery life. The subsystem has been fine-tuned to ensure smooth operation and efficient energy usage.

Please find the attached code and images below for further reference.

- Components used: ATmega328PB board, breadboard, connecting wires, IRLB8721 Mosfet, 10k ohm resistor and DC cooling fan.

Main Code

/*

* File: Fan_control.c

* Author: Megha31

*

* Created on 14 November, 2024, 2:20 PM

*/

#include <stdio.h>

#include <stdlib.h>

#include <avr/io.h>

/*

*

*/

#ifndef F_CPU

#define F_CPU 16000000UL // CPU frequency set to 16MHz

#endif

#include <avr/io.h>

#include <util/delay.h>

void timer1_init(void) {

// Set PB1 (OC1A) as output

DDRB |= (1 << PB1);

// Configure Timer1 for Fast PWM mode

// WGM13:0 = 1110 for Fast PWM mode with ICR1 as TOP

TCCR1A |= (1 << WGM11);

TCCR1B |= (1 << WGM13) | (1 << WGM12);

// Set COM1A1:0 = 10 for non-inverting PWM on OC1A (PB1)

TCCR1A |= (1 << COM1A1);

TCCR1A &= ~(1 << COM1A0);

// Set prescaler to 1 (no prescaling)

TCCR1B |= (1 << CS10);

// Set PWM frequency to about 25kHz

// F_PWM = F_CPU / (prescaler * (1 + TOP))

// 16000000 / (1 * (1 + 639)) ? 25kHz

ICR1 = 639;

}

void set_fan_speed(uint8_t speed_percent) {

// Limit speed_percent to 0-100 range

if (speed_percent > 100) {

speed_percent = 100;

}

// Calculate OCR1A value based on speed percentage

// OCR1A determines duty cycle

uint16_t ocr_value = (uint16_t)((ICR1 + 1) * speed_percent / 100) - 1;

OCR1A = ocr_value;

}

int main(void) {

// Initialize Timer1 for PWM

timer1_init();

while (1) {

// Example speed control pattern

// Run at 0% speed

set_fan_speed(0);

_delay_ms(6000);

// // Run at 25% speed

set_fan_speed(25);

_delay_ms(6000);

//

// // Run at 50% speed

set_fan_speed(50);

_delay_ms(6000);

//

// // Run at 75% speed

set_fan_speed(75);

_delay_ms(6000);

//

// // Run at full speed

set_fan_speed(100);

_delay_ms(6000);

}

return 0;

}

uart.c file

/*

* File: uart.c

* Author: Megha31

*

* Created on 16 November, 2024, 12:52 PM

*/

#include "uart.h"

#include <stdarg.h>

static char uart_buffer[UART_BUFFER_SIZE];

void uart_init(void) {

// Set baud rate

UBRR0H = (uint8_t)(BAUD_PRESCALER >> 8);

UBRR0L = (uint8_t)(BAUD_PRESCALER);

// Enable transmitter and receiver

UCSR0B = (1 << TXEN0) | (1 << RXEN0);

// Set frame format: 8 data bits, 1 stop bit, no parity

UCSR0C = (1 << UCSZ01) | (1 << UCSZ00);

}

void uart_putchar(char c) {

// Wait for empty transmit buffer

while (!(UCSR0A & (1 << UDRE0)));

// Put data into buffer, sends data

UDR0 = c;

}

void uart_puts(const char* str) {

while (*str) {

uart_putchar(*str++);

}

}

void uart_printf(const char* format, ...) {

va_list args;

va_start(args, format);

vsnprintf(uart_buffer, UART_BUFFER_SIZE, format, args);

uart_puts(uart_buffer);

va_end(args);

}

uart.h file

/*

* File: uart.h

* Author: Megha31

*

* Created on 14 November, 2024, 6:00 PM

*/

#ifndef UART_H

#define UART_H

#ifndef F_CPU

#define F_CPU 16000000UL

#endif

#define BAUD_RATE 9600

#define BAUD_PRESCALER ((F_CPU / (BAUD_RATE * 16UL)) - 1)

#include <avr/io.h>

#include <stdio.h>

// UART buffer size

#define UART_BUFFER_SIZE 64

// Function declarations

void uart_init(void);

void uart_putchar(char c);

void uart_puts(const char* str);

void uart_printf(const char* format, ...);

#endif

Hydration Level Computation

- We also completed computing basic hydration levels based on GSR data. We used an existing dataset (Dataset) of GSR readings and employed a Random Tree Classifier to analyze the data and estimate hydration levels. The classifier was trained to identify patterns in the GSR readings that correlate with hydration status, and it has shown promising results in predicting hydration levels (hydrated, medium hydration and dehydrated) with 100% accuracy.

Please find the attached code and images below for your reference.

import pandas as pd

from sklearn.model_selection import train_test_split, GridSearchCV, learning_curve

from sklearn.preprocessing import StandardScaler

from sklearn.ensemble import RandomForestClassifier

from sklearn.metrics import accuracy_score

from sklearn.preprocessing import LabelEncoder

import matplotlib.pyplot as plt

import matplotlib

# Set matplotlib to use the Agg backend (for PyCharm or headless environments)

matplotlib.use('Agg')

# Function to convert stress level to hydration level

def stress_to_hydration(stress_level):

if stress_level == 'Low Stress': # Hydrated

return 'Hydrated'

elif stress_level == 'Medium Stress': # Medium Hydration

return 'Medium Hydrated'

elif stress_level == 'High Stress': # Dehydrated

return 'Dehydrated'

# Load the dataset from a CSV file

df = pd.read_csv('C:/Users/geniu/Desktop/datasetFinal1.csv')

# Check if the CSV has the expected columns (GSR and Stress_Level)

if 'GSR' not in df.columns or 'Stress_Level' not in df.columns:

raise ValueError("The CSV file must contain 'GSR' and 'Stress_Level' columns.")

# Apply the hydration level function to each row based on the Stress_Level

df['Hydration_Level'] = df['Stress_Level'].apply(stress_to_hydration)

# Encode the 'Hydration_Level' (target) column into numeric labels

le = LabelEncoder()

df['Hydration_Level_Label'] = le.fit_transform(df['Hydration_Level'])

# Feature and target variables

X = df[['GSR']] # Features (GSR values)

y = df['Hydration_Level_Label'] # Target (Hydration Levels)

# Normalize the features (GSR values) to improve performance for models like Random Forest

scaler = StandardScaler()

X_scaled = scaler.fit_transform(X)

# Split the data into training and testing sets

X_train, X_test, y_train, y_test = train_test_split(X_scaled, y, test_size=0.2, random_state=42)

# Print the number of samples being trained and tested

print(f"Training Samples: {X_train.shape[0]}")

print(f"\nTest Samples: {X_test.shape[0]}")

# Initialize a Random Forest Classifier

rf_classifier = RandomForestClassifier(random_state=42)

# Optionally, perform hyperparameter tuning with GridSearchCV

param_grid = {

'n_estimators': [100, 200, 300],

'max_depth': [10, 20, 30],

'min_samples_split': [2, 5, 10],

'min_samples_leaf': [1, 2, 4]

}

# Use GridSearchCV to find the best hyperparameters

grid_search = GridSearchCV(estimator=rf_classifier, param_grid=param_grid, cv=5, n_jobs=-1, verbose=2)

grid_search.fit(X_train, y_train)

# Get the best estimator from GridSearchCV

best_rf_classifier = grid_search.best_estimator_

# Train the model on the training data

best_rf_classifier.fit(X_train, y_train)

# Get the best number of estimators from the grid search

best_n_estimators = best_rf_classifier.n_estimators

# Calculate the total operations (trees * samples)

total_operations = best_n_estimators * X_train.shape[0]

print(f"\nTotal Operations: {total_operations} operations")

# Make predictions on the test set

y_pred = best_rf_classifier.predict(X_test)

# Compute accuracy

accuracy = accuracy_score(y_test, y_pred)

print(f'\nAccuracy: {accuracy * 100:.2f}%')

# Optionally, print feature importance

print("\nFeature Importances:")

print(best_rf_classifier.feature_importances_)

# Optionally, print the classification results for test samples

print("\nPredictions on Test Set:")

print("Predicted Hydration Levels:")

print(le.inverse_transform(y_pred))

# Optionally, save the updated data with predictions to a new CSV file

df['Predicted_Hydration_Level'] = le.inverse_transform(best_rf_classifier.predict(X_scaled))

df.to_csv('hydration_levels_with_predictions.csv', index=False)

# Get the learning curve data

train_sizes, train_scores, test_scores = learning_curve(best_rf_classifier, X_train, y_train, cv=5)

# Debugging: Print the learning curve data

print("\nTrain Sizes: ", train_sizes)

print("\nTrain Scores: ", train_scores)

print("\nTest Scores: ", test_scores)

# Check if the shape of arrays is correct

print("\nTrain Sizes Shape:", train_sizes.shape)

print("Train Scores Shape:", train_scores.shape)

print("Test Scores Shape:", test_scores.shape)

# Calculate mean and standard deviation of training and testing scores

train_mean = train_scores.mean(axis=1)

test_mean = test_scores.mean(axis=1)

# Plot learning curves (will save the plot as an image)

plt.plot(train_sizes, train_mean, label="Training Score", color="blue", linestyle='-', marker='o')

plt.plot(train_sizes, test_mean, label="Validation Score", color="green", linestyle='--', marker='x')

plt.xlabel("Training Size")

plt.ylabel("Score (Accuracy)")

plt.title("Learning Curve")

plt.legend()

# Save the plot to a file (no need to display it interactively)

plt.savefig('learning_curve.png') # Saves as a PNG image

# Optionally, close the plot to avoid any issues with PyCharm

plt.close()

The image shows a learning curve plot with Training Score and Validation Score as a function of Training Size.

- Training Score (in blue) is consistently high at 1.0 across all training sizes, indicating perfect accuracy during training.

- Validation Score (in green, dashed line) starts lower (around 0.8 for smaller training sizes) but quickly rises to nearly 1.0 as the training size increases.

- After reaching around 40 training samples, both the training and validation scores stabilize, indicating minimal variance and no overfitting.

Overall this plot suggests that the model is performing very well, with both training and validation accuracy being close to perfect.

Next week’s plan

Task: Build GSR Dataset and Calibration

- Description: Generate and calibrate the GSR sensor using real user GSR data (currently, team members will act as test subjects by drinking different amounts of water). The goal is to create a dataset for the ML model, which will use skin resistance thresholds to estimate water loss in F1 drivers and also control the cooling subsystem.

- Estimated Time: 4 days

- Assigned Team Member: Chirag Satapathy

- Definition of Done: Develop a calibrated dataset of GSR data, including approximate skin resistance thresholds. This data will be used by the ML model to calculate water loss and provide control parameters for the cooling subsystem.

Task: Test Cooling Subsystem with GSR Dataset

- Description: Optimise the fan control code for serial monitoring. Using the GSR dataset generated from real user data (i.e., skin resistance levels), we will test and calibrate the cooling subsystem. The dataset will be analyzed to establish hydration-related skin resistance thresholds, which will inform the cooling mechanism’s response. The cooling subsystem will be adjusted to react dynamically to the hydration status of the wearer, based on GSR readings, to ensure optimal performance. Also to find an alternative to IRLB8721 MOSFET component as it heats up quickly.

- Estimated Time: 3 days

- Assigned Team Member: Megha Mistry

- Definition of Done: Successfully test and calibrate the cooling subsystem, ensuring it responds accurately to changes in skin resistance (as reflected by the GSR dataset). The system should adjust the cooling intensity based on hydration levels, providing optimal comfort to the F1 driver (wearer).

Task: Pulse Oximeter Accurate Sensor Reading

- Description: Address the issue with the pulse oximeter sensor, which is currently only outputting static values. We will focus on debugging the sensor to ensure dynamic, accurate readings of blood oxygen levels. The sensor will be tested in both steady-state and dynamic conditions (e.g., running or jogging).

- Estimated Time: 3 days

- Assigned Team Member: Sanskriti Binani

- Definition of Done: Resolve the issue with static readings, achieving consistent and accurate pulse oximeter data under both steady-state and dynamic conditions.

Task: LoRa Module Final Testing

- Description: Test the range of LoRa modules in real-world environments, assessing signal strength over various distances and environmental conditions (like open areas and long distances with rapid movement).

- Estimated Time: 3 days

- Assigned Team Member: Chirag Satapathy, Sanskriti Binani, Megha Mistry

- Definition of Done: Resolve the issue with static readings, achieving consistent and accurate pulse oximeter data under both steady-state and dynamic conditions.

Sprint review trial

Current state of project

-

Currently, we are in the process of completing the initial setup of the LoRa modules and preparing to verify basic data transmission over short ranges. Our main focus will be on testing range, accurately sending and receiving data from LoRa 1 to LoRa 2 and also power efficiency.

-

We are also trying to figure out the most apt machine learning model to compute the accurate water loss levels of the F1 driver by intensive reading of existing research and articles.

Last week’s progress

-

Completed ordering all the required components for our project.

-